Our Services

Product Design

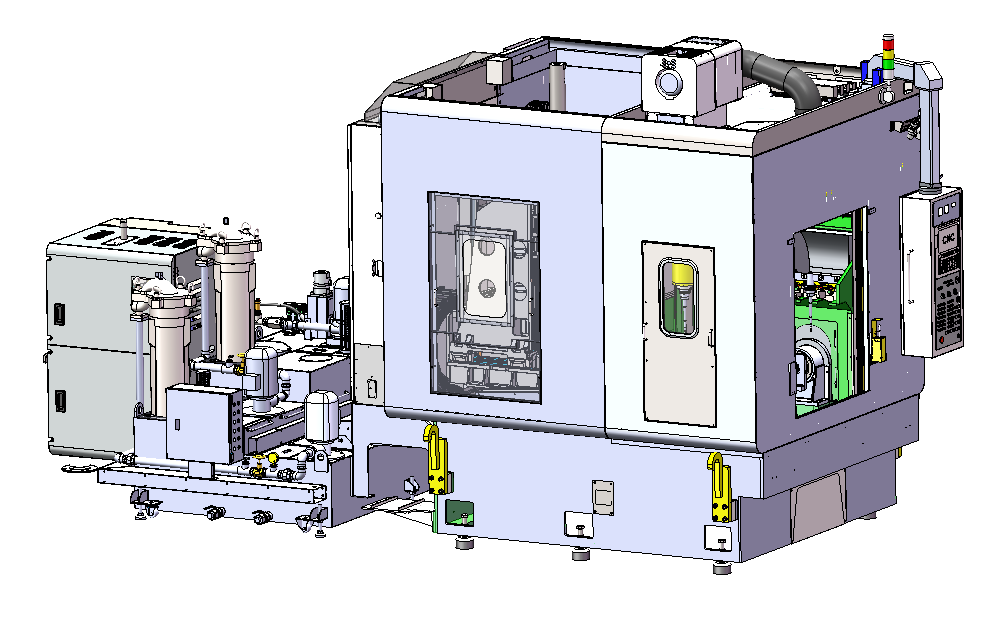

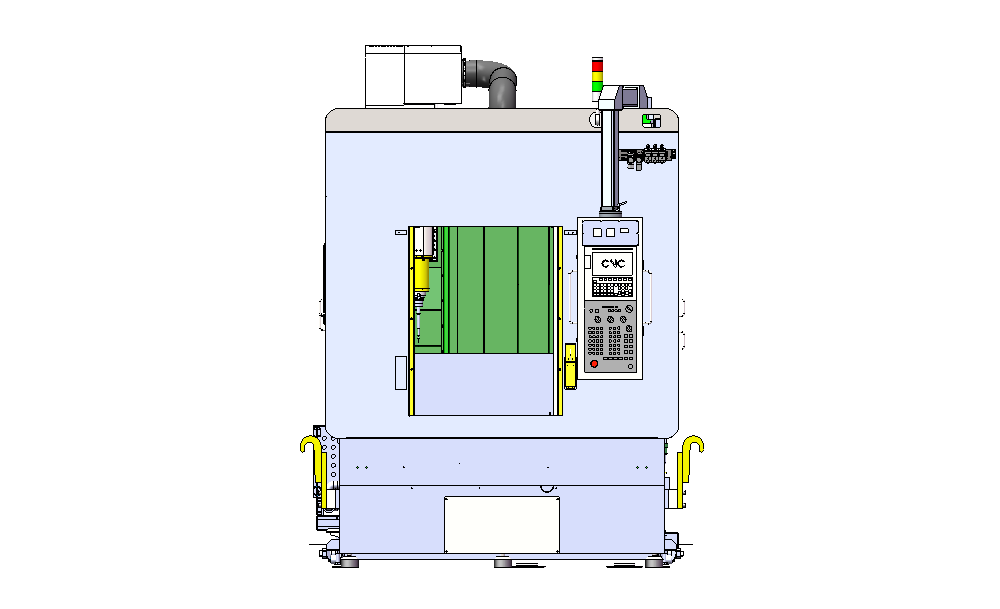

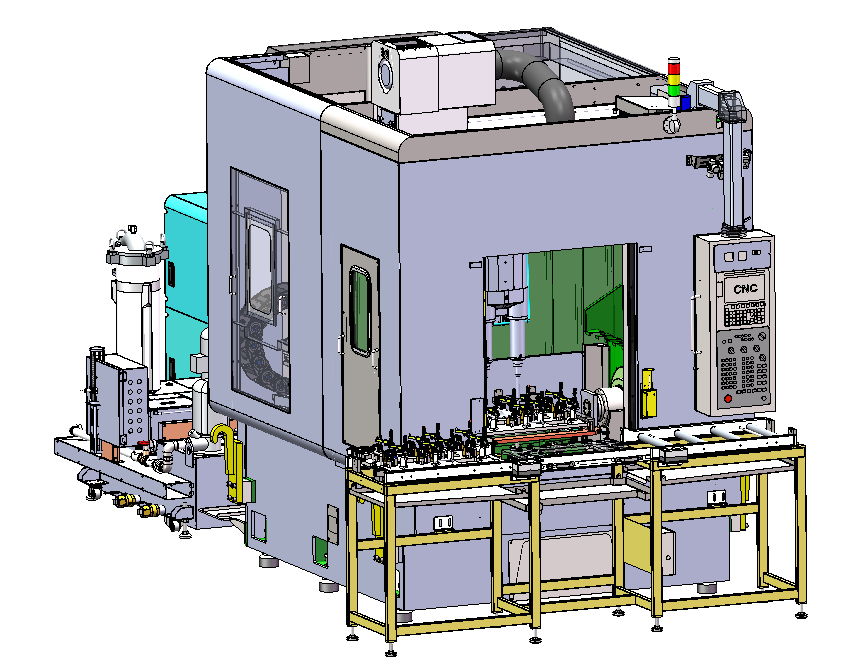

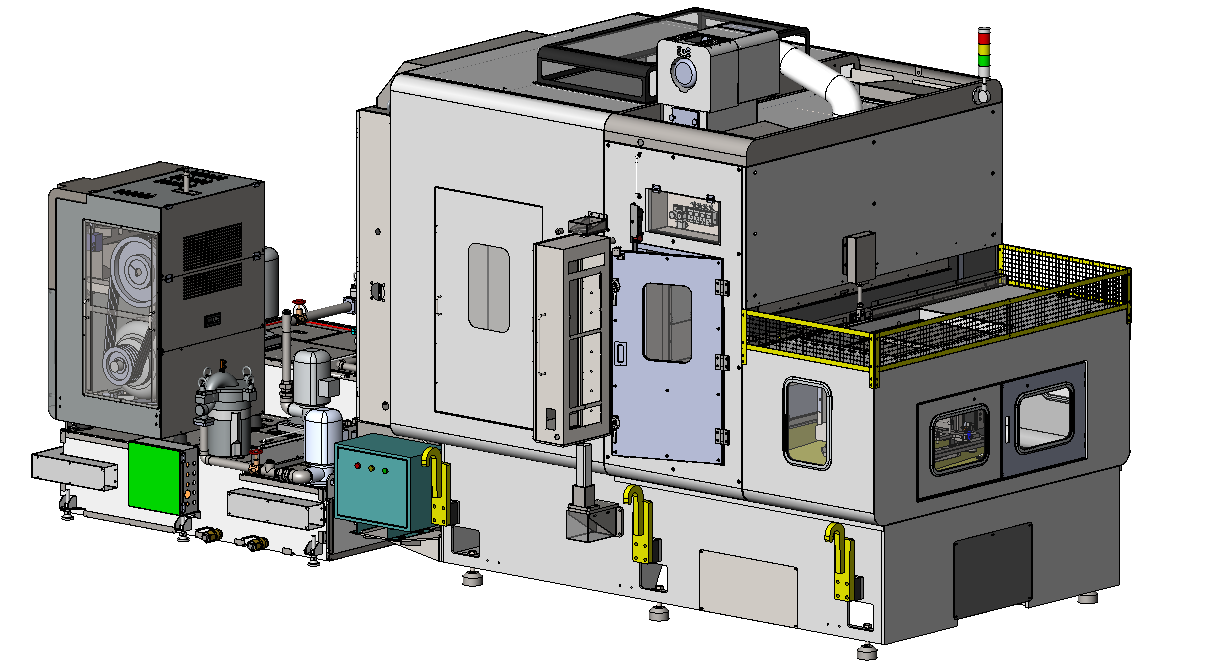

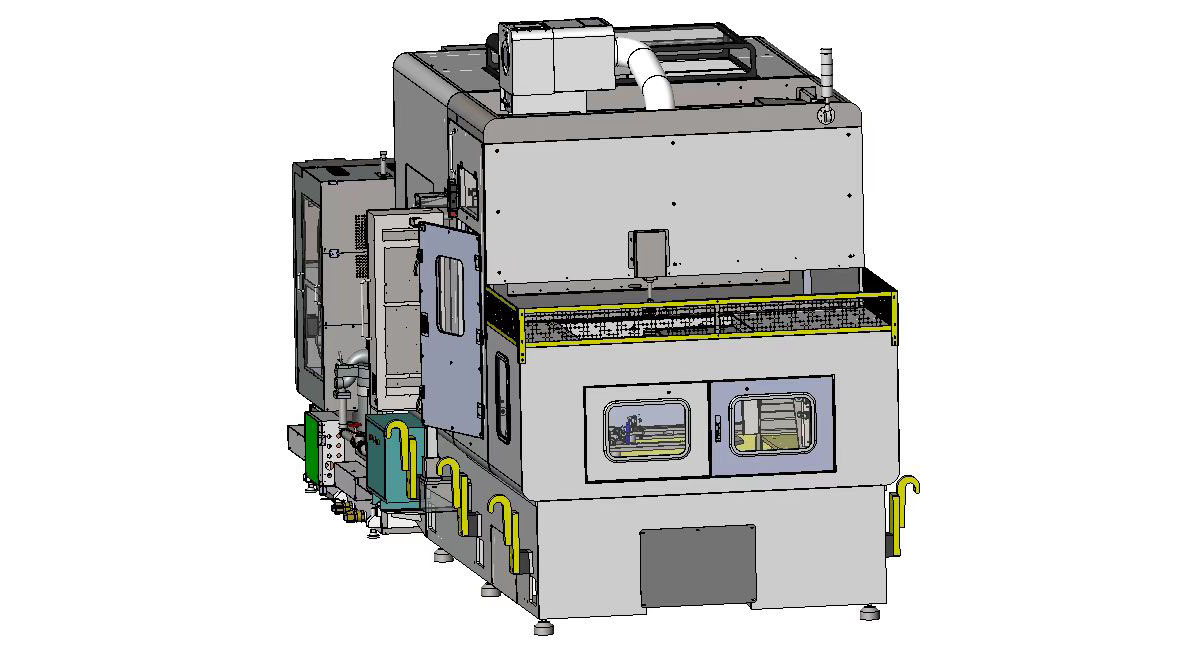

The i-MOVAC series is the crystallization of our experience and technology accumulation in the high-pressure cleaning center industry of over a decade. The relevant core technologies have reached and surpassed the international level.

The i-MOVAC model is a 500KG high-pressure cleaning center equipped with intelligent pressure-regulating system. It can remove residues such as burrs, oil, particulates and impurities produced in processing from workpieces, and clean up the surface and internal structure of workpieces completely, to meet or exceed the cleanliness requirements for assembling without any damage to workpieces.

Features:

With the adoption of high-precision CNC rotary table, the equipment can clean up six surfaces of a workpiece accurately and efficiently in one clamping. Equipped with the FANUC system, the cleaning equipment can reach the repositioning accuracy of ±0.05mm, so as to clean and deburr workpiece parts such as small holes, deep holes and cross holes with precision and efficiency. Due to its patented automatic nozzle change system, it can change nozzle automatically according to the different requirements of cleaning different parts of workpieces. In addition, it can customize, produce and install automatic tooling based on the features of specific workpiece. Thus, it realizes integration with automatic production line, improves production efficiency, saves time and reduces labor cost.

Advantages:

I. Energy conservation: The high-pressure cleaning center adopts industrial soft water as recyclable cleaning medium.

II. Wide range of application: The i-MOVAC high-pressure cleaning center series is mainly used in aeronautics & astronautics, automobile manufacturing, new energy, engineering machinery and other high-precision parts.

III. Lower workpiece manufacturing cost: Developed based on the technical advantages of the Japan R&D center and China’s current workpiece processing technologies, the international advanced CNC high-pressure cleaning center i-MOVAC can reduce the deburring cost to less than 1% of the total manufacturing cost.

IV. Comparison with other technological processes:

Cleaning and deburring are the last process of the workpiece processing line. Conventionally, deburring is conducted manually with tools such as hairbrush, followed with cleaning with ultrasonic and low-pressure cleaning equipment. High-pressure water is the best means of cleaning and deburring components—especially high-precision components. Furthermore, high-pressure water can be recycled to save energy and protect the environment. With the heightening of awareness of environmental protection and the promotion of environment-friendly products globally, high-pressure cleaner has become essential for improving product quality. The utilization of high-pressure cleaner is already an inevitable trend.

V. Inevitable trend of machining

Currently, imported high-pressure cleaning centers are not received well in the market due to high price. In comparison, the high-pressure cleaning centers produced by FE-MOVAC has good performance and a competitive price. The 50Mpa high-pressure cleaning center developed by FE-MOVAC has changed the situation of a domestic market dominated by imported high-end cleaning centers.